Quality

For us, responsibility means consistently ensuring quality and offering our customers the highest level of security. Components at Service supplies renowned customers in the automotive, aerospace, and medical technology sectors, where even the smallest quality issues can have serious consequences. We understand this responsibility and, therefore, adhere to the most advanced and rigorous quality assurance standards. The definition of quality, along with the associated processes and measures, is closely aligned with the high demands of our customers and partners.

At CAS, quality assurance starts with procurement. Our suppliers are carefully selected and strictly audited, and we source electronic components and IT hardware exclusively from reliable, well-known, and audited sources. To technically ensure high quality standards in procurement and collaboration with our suppliers, we established the state-of-the-art testing lab, CAS Q-LAB, in cooperation with a leading research institute, directly at our headquarters in Oberhaching near Munich, Germany.

The CAS Q-LAB

As a leading distributor of electronic components and IT hardware, we see it as our special responsibility to protect our customers and partners from quality issues and counterfeits. With the CAS Q-LAB, we have established a state-of-the-art testing lab equipped with the latest technology and proven testing methods to thoroughly inspect our components. This allows us not only to detect potential damages from transport, storage, or electrostatic discharge, but also to eliminate the risk of counterfeits.

The CAS Q-LAB

As a leading distributor of electronic components and IT hardware, we see it as our special responsibility to protect our customers and partners from quality issues and counterfeits. With the CAS Q-LAB, we have established a state-of-the-art testing lab equipped with the latest technology and proven testing methods to thoroughly inspect our components. This allows us not only to detect potential damages from transport, storage, or electrostatic discharge, but also to eliminate the risk of counterfeits.

With the Q-LAB, we offer you:

The highest standards in quality assurance

Research and development projects in collaboration with customers, universities, and leading institutes

Quality assurance training programs

Quality assurance in the Q-LAB is aligned with our customers in the automotive, aerospace, and medical technology sectors to meet the highest standards.

In addition to our own testing lab, we also collaborate with independent accredited labs and institutes to verify quality, functionality, and authenticity—all for the protection of our customers and partners.

Our Services and Capabilities in the Q-LAB

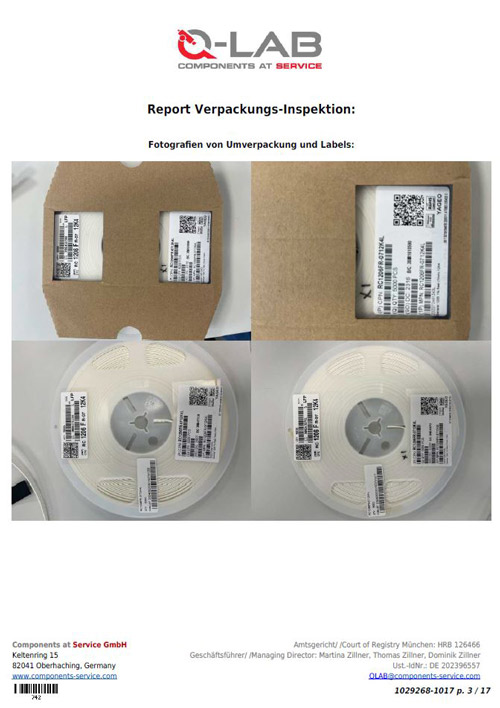

Verification of labeling and packaging

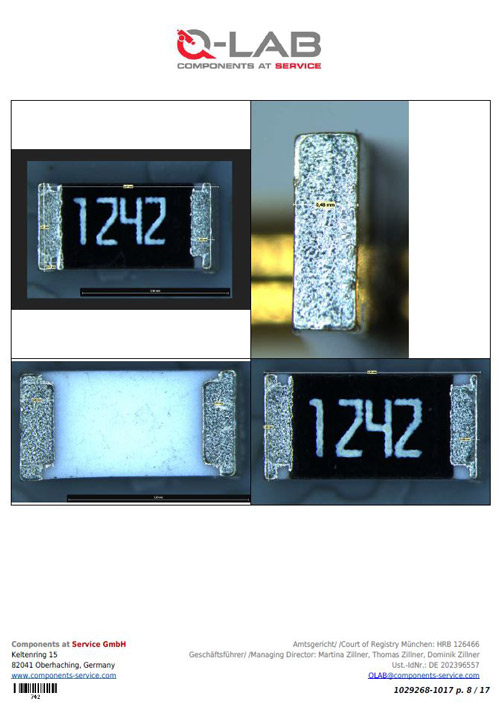

Visual inspection (optical and X-ray)

Functional testing and material analysis

Our Testing Spectrum:

ESD Test: Packaging

Visual Inspection

Re-marking and Surface Tests

Decapsulation

X-ray Examination

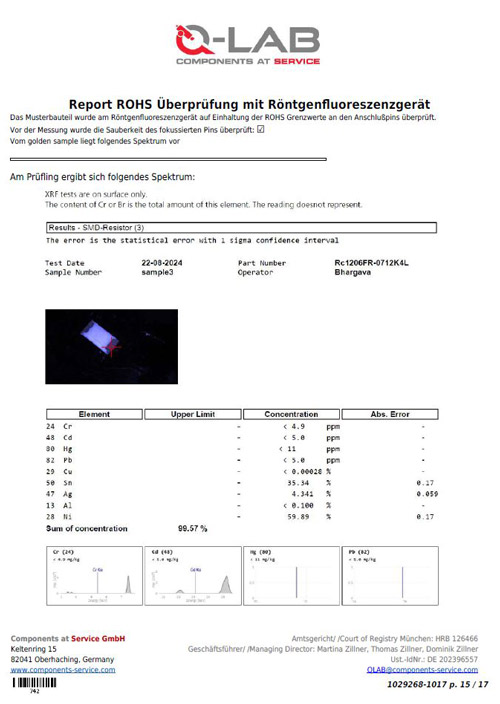

XRF Material Analysis

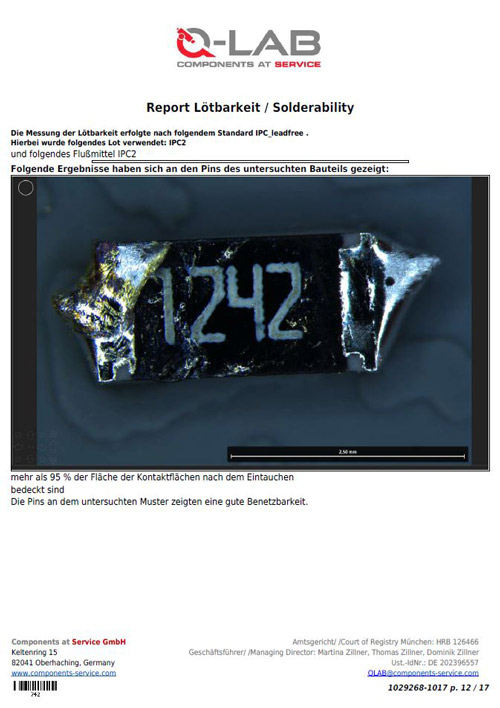

Solderability Testing

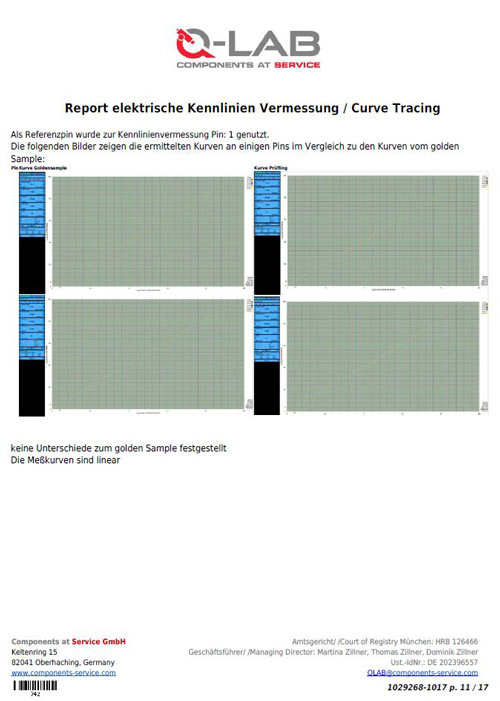

Electrical Testing

Programming Test

Highest Quality – State-of-the-Art Equipment

Leica M205C

Microscope

Tektronix DMM6500

Digital Multimeter

TruView Prime R

X-Ray System

Spectro Cube

X-ray Fluorescence Analyzer

Abi Sentry

Counterfeit IC Detector

JetEtch Pro

Chemical Decapsulation

LAC LZ03/12

Thermal Decapsulation

MUST3 System

Solderability Tester

Tektronix TBS 1154

Digital Oscilloscope

Tektronix 2600-PCT-2B

Sourcemeter

SourcetronicST289C

LCR Meter

SG-RI01

In-Tape Inspection System

W-TECH

T&R System

HT-EUREP

T&R Rework Station

ElnecBeeProg2C

Programmer

G&G JJ100B

Precision Scale

SuperDryXSDB-1412-55

Drying Oven

Keysight 33120

Function Generator

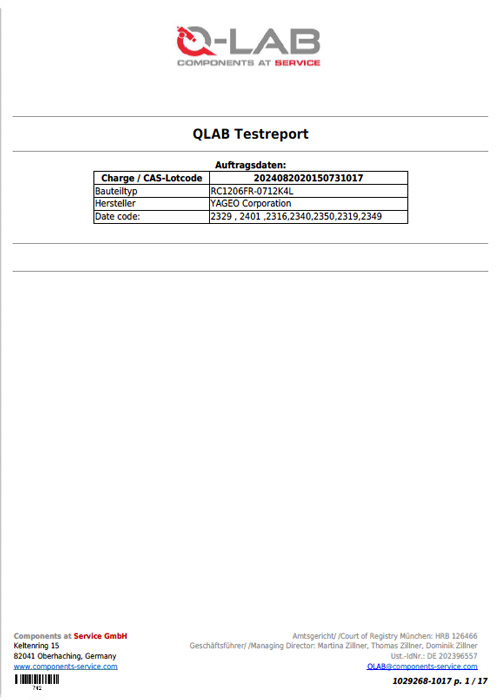

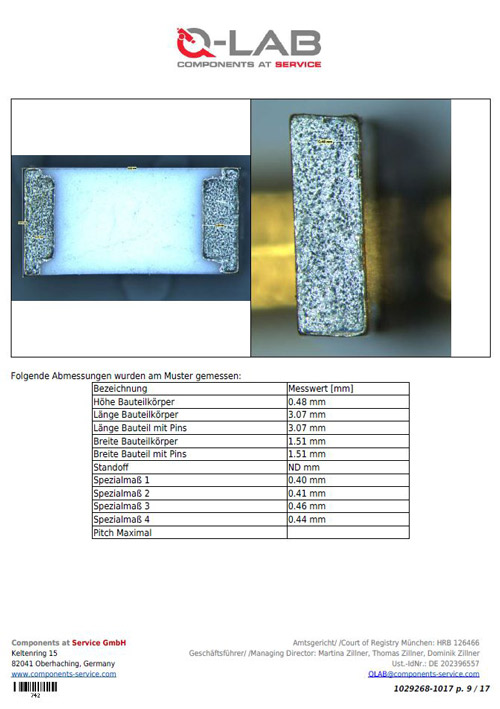

Provision of Detailed Test Reports (Sample Excerpt)

Our Suppliers

At CAS, quality assurance begins with procurement. Our suppliers are selected based on strict criteria and routinely undergo on-site audits, where we review processes, ethical standards, and equipment. Regular re-audits ensure long-term stability and reliability. We evaluate factors such as quality consistency, inventory management, punctuality, material origin, and safety and environmental compliance.

Our proprietary supplier portal, the “CAS Smart Inquiry Tool,” enables real-time monitoring of supplier performance, incorporating key metrics such as response time, pricing, feedback rate, and reliability.

At CAS, we leave nothing to chance!

Our Employees

Quality can only be ensured and maintained by motivated, qualified employees, which is why we offer our team individual development opportunities as well as individual training and continuing education.

Components at Service GmbH gives all employees an opportunity to realize and advance their own projects.

Such a basis of trust results in long-term intrinsic motivation and thus to maximum customer satisfaction.

Our Employees

Quality can only be ensured and maintained by motivated, qualified employees, which is why we offer our team individual development opportunities as well as individual training and continuing education.

Components at Service GmbH gives all employees an opportunity to realize and advance their own projects.

Such a basis of trust results in long-term intrinsic motivation and thus to maximum customer satisfaction.

Our Processes

We are certified according to DIN EN ISO 9001: 2015. This means that all our processes are strictly regulated according to the requirements of this quality standard.

DIN EN ISO 9001:2015 is the most widely used, most important quality management standard, both nationally and internationally. It serves as a basis for a continuous improvement process, first and foremost to fulfil customer requirements and to strive to meet customer expectations.

Our Warehouses

Our warehouses are specifically designed for the secure and professional storage of electronic components, maintained in a temperature- and humidity-controlled, ESD-protected environment (in accordance with DIN EN 61340-5-1/-5-3). To protect against electrostatic discharge and meet strict customer requirements, the entire area is equipped with cameras, access control, and fire safety measures.

goods entry and exit are photo-documented and digitally recorded. Each batch receives a unique CAS-LOT number for complete traceability. With a single click, critical information—such as supplier, components receipt, storage location and duration, components issue, customer, item images, documents, and test results—can be accessed.

Our warehouse setup is optimized to ensure smooth components receipt and dispatch, minimize errors, and maintain high punctuality and quality.

Our Warehouses

Our warehouses are specifically designed for the secure and professional storage of electronic components, maintained in a temperature- and humidity-controlled, ESD-protected environment (in accordance with DIN EN 61340-5-1/-5-3). To protect against electrostatic discharge and meet strict customer requirements, the entire area is equipped with cameras, access control, and fire safety measures.

goods entry and exit are photo-documented and digitally recorded. Each batch receives a unique CAS-LOT number for complete traceability. With a single click, critical information—such as supplier, components receipt, storage location and duration, components issue, customer, item images, documents, and test results—can be accessed.

Our warehouse setup is optimized to ensure smooth components receipt and dispatch, minimize errors, and maintain high punctuality and quality.

Location

Keltenring 15

82041 Oberhaching